Menu

Testek Solutions has a versatile system to test all of your pneumatic components – including the Next Generation.

Test Pneumatic Components for Your Entire Fleet

A system for testing the ACM and every other component in the ECS

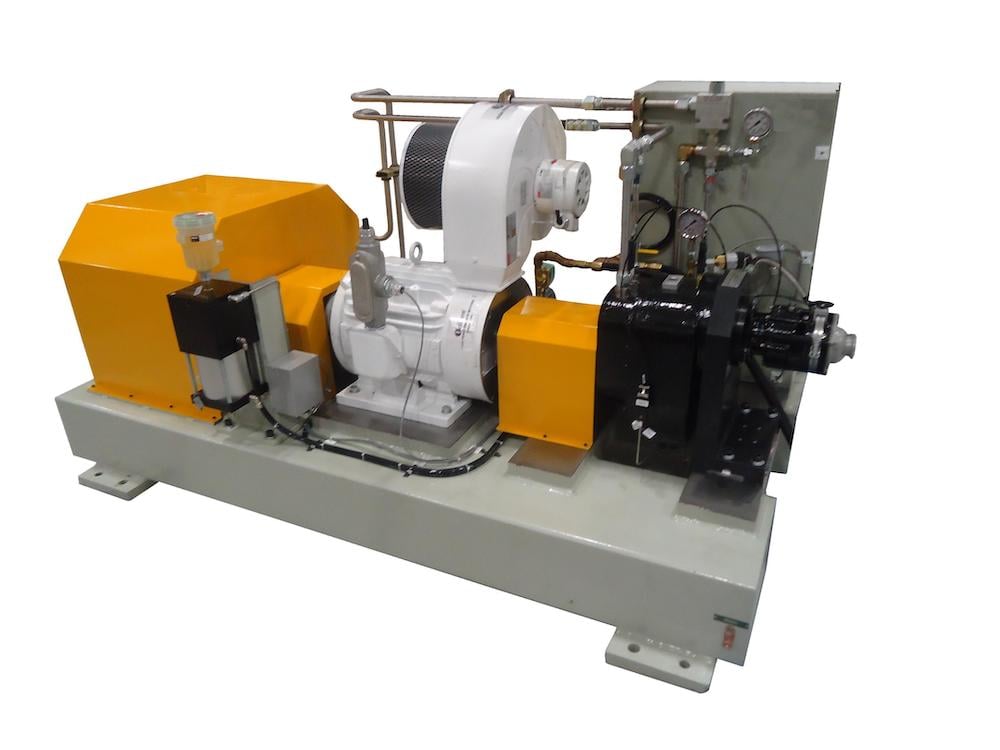

The Testek Solutions ECS Test System is ready for the next generation. In addition to the pneumatic pressure, temperature, data acquisition, and vibration measurement circuits required to test an ACM, our ECS test system has the Air Management System (AMS) Drive Center (ADC) motor controller, low temperature chillers, and vacuum circuits necessary to test Cabin Air Compressors (CAC), Ram Air Fans (RAF), and Motor Driven Compressors (MDC).

Variety. Safety. Accessibility.

For more than 50 years, Testek Solutions has designed, manufactured, and supported highly reliable aerospace and defense test equipment and testing facilities for OEMs, MROs, and operators.