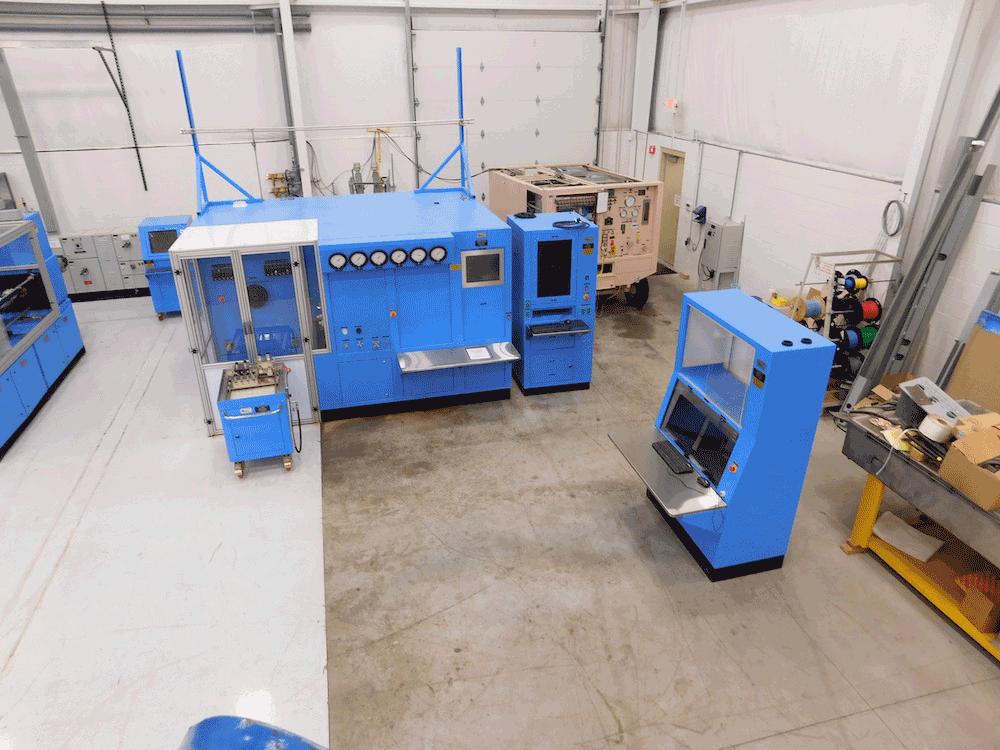

Control and flexibility.

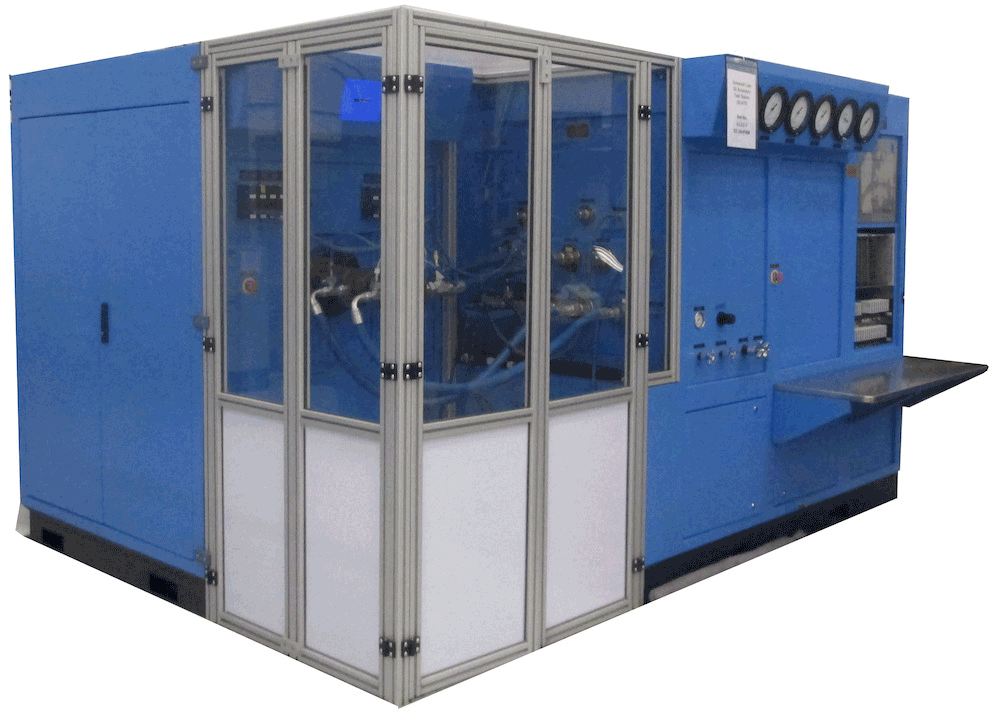

Testek’s lube oil test solutions are designed for maximum control of critical test variables, such as heat. An integrated reservoir helps to keep fluid temperature consistent – fluid tanks and lines are also insulated to prevent excess heat loss during transfer. Testek’s design utilizes silicon controlled rectifier (SCR) heater controllers, which offer precise control and reliability. Our test software automatically compensates for temperature variation to provide more accurate flow readings. The heating and cooling system uses cooling air from outside the test enclosure to prevent contaminating the motor with oil-saturated air. Mass flowmeters are also available for high-temperature, high-accuracy flow requirements.

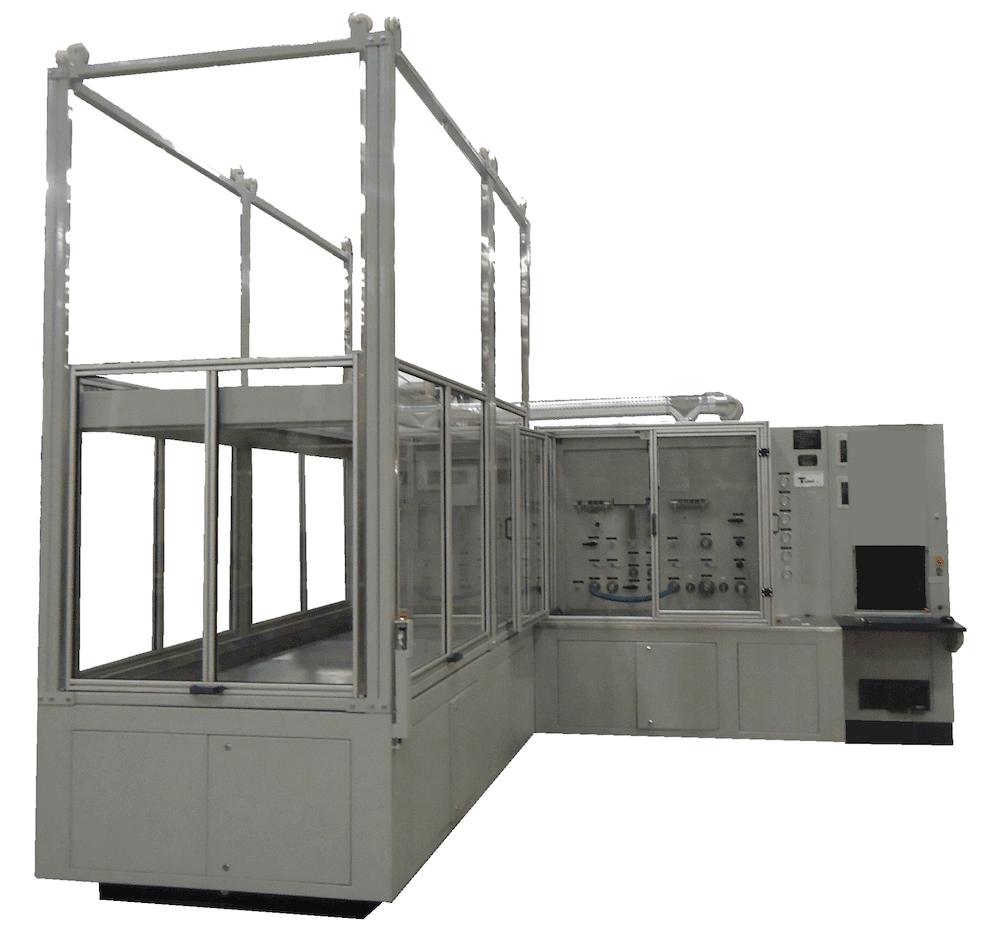

The Testek model Lube Oil Component Test Stand is designed to grow with your needs. Testek uses a modular design approach for these test stands that helps to minimize the cost of future modifications for later models and new applications. A larger drive/pumping system is available as an option in some models.

Our Lube Oil Test Stands offer accessibility, efficiency, and options.

Testek’s lube oil test stands optimize use of resources. The test stands include an integrated test sink. A scavenge system automatically collects oil waste from testing and directs it through a filter system. The filtered oil is returned to the main oil reservoir for reuse.

For more than 55 years, Testek Solutions has designed, manufactured, and supported highly reliable aerospace and defense test equipment and testing facilities for OEMs, MROs, and operators.